The requirements on seals are increasing steadily due to the demand for cost-conscious process security, increasing environmental consciousness, and of course statutory regulations. As a result of the experience gained during decades of working with different industries, we are able to provide proven products that are specifically designed for the various applications.

Our team also embraces new challenges with professional competency and know-how, and creates materials through continuous development and innovation that meet customers' individual requirements.

From chamber frame seals in coking plants to the sealing of smelting furnaces in the primary aluminium industry, the sealing of doors, covers and hatches in industrial boiler construction, including application in power stations and the glass industry – the diversified fields of application of our packings speak for themselves.

This is not only due to the top quality of our materials, but in particular because our packings are characterised by high efficiency due to low shrinkage and loss on ignition, mechanical strength, a high sealing effect and are safe for humans. Tell us your technical challenges. We promise to find a solution that leaves nothing to be desired.

Complex designs of thermal plants and process-dependent varying gap sizes as well as limited space for seals due to the design require flexible solutions. Flexible and adaptable seals are the prerequisite for meeting such specific demands.

Due to our broad range of cords we are able to provide the best solutions also for complex and the most varied applications.

Our many different types of ropes are preferred for the sealing of doors in the construction of chimneys and laboratory furnaces, but also barrier seals of casting launders. Twisted cords on the other hand are preferred in the foundry for ingot mould seals as well as for exhaust gas plants in the thermal processing industry. Our braided cords are used in air conditioning and ventilation systems in the thermal processing industry.

Having a thickness of up to 50 mm they are often used as partial surface covers, as conveyor belts or to prevent electrical discharge.

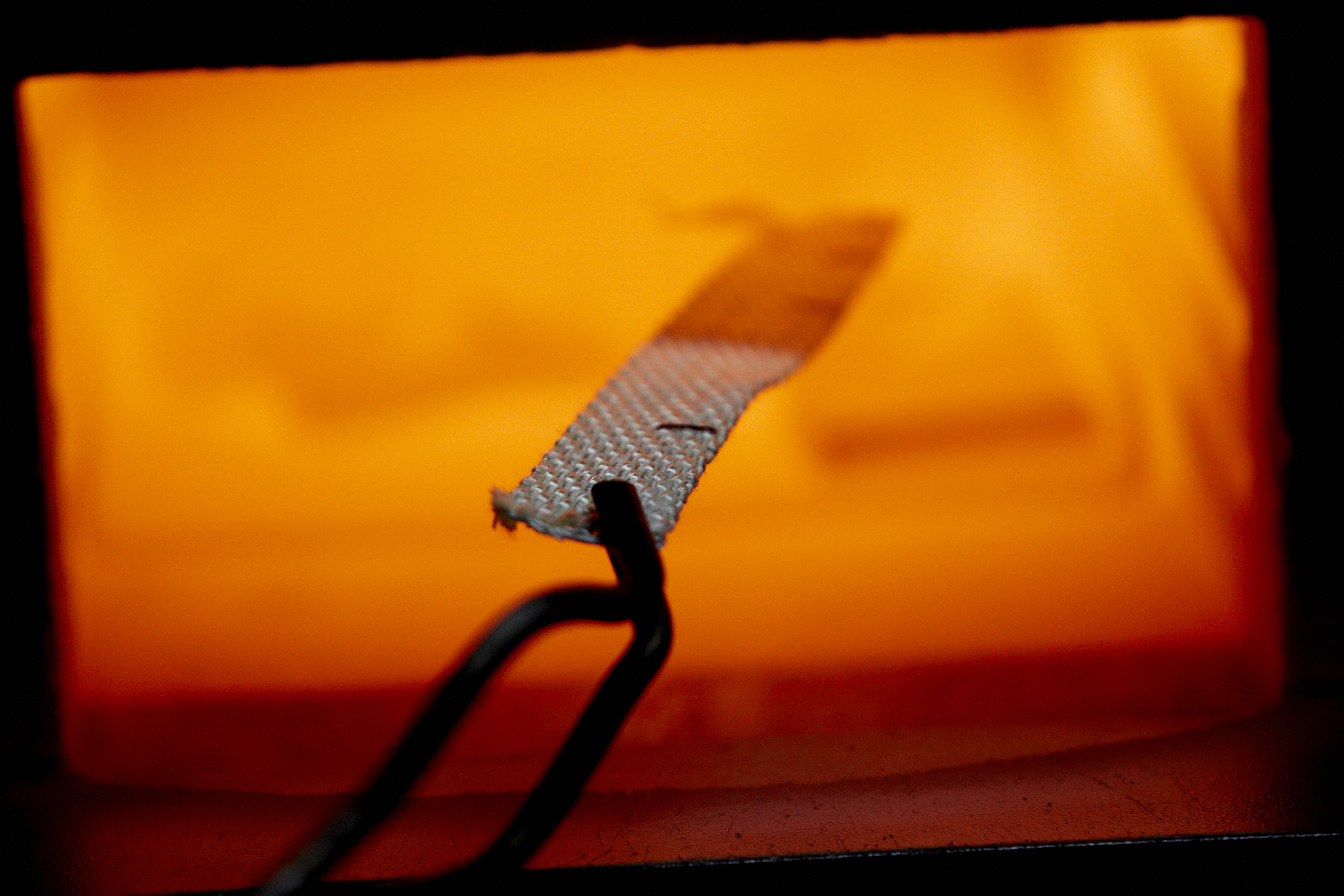

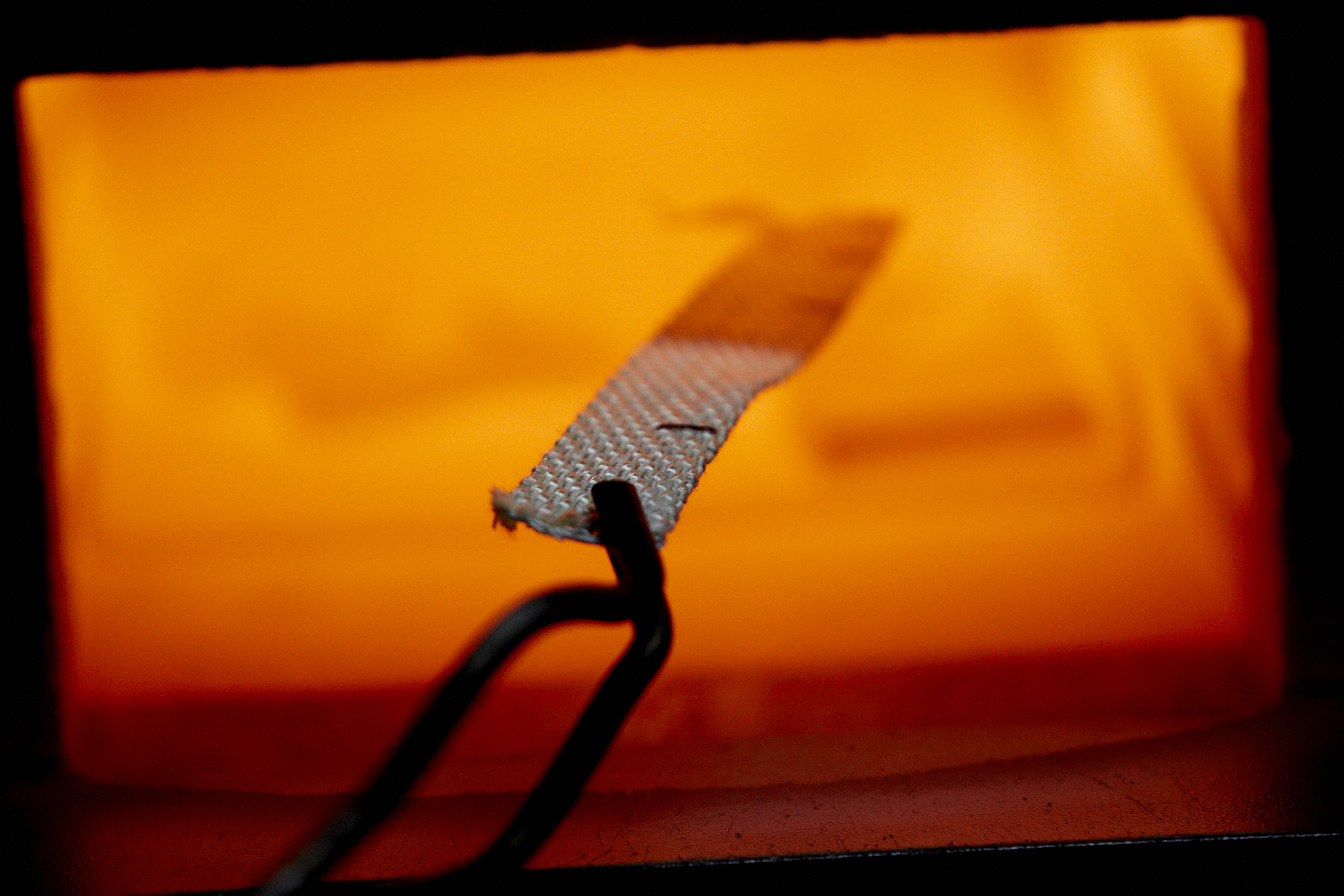

This material is preferred in the construction of furnaces as door seal and as inner insulation for the glass screen, in the construction of industrial furnaces as door seal or in coal-fired power stations and in the cement industry as permeable conveyor belt.

We are providing belts in different designs that are finished or coated for particular applications. This way you always get the best product from us because the special finish is adapted to your requirements and thus optimises the life span, the down-times, resistance to wear, the sealing properties and at the same time reduces thermal bridges.

Moreover, the application of different weaving techniques and material components provide an opportunity to influence the technical characteristics such as tensile strength, wear resistance and touch allowing it to adapt perfectly for the respective application.

Some situations require dedicated solutions. If our extensive range of packings, cords and belts does not include the material for your requirements, the ideal solution could be profiled seals and multi-layered woven belts.

Our team of experts develops and manufactures the materials specifically for the requirements of our plant and provides you with numerous possible combinations and dimensions. Through professional tailoring and selection of profile components we guarantee the best possible result for your application.

Our profiled seals are used in plants where the restoring force or the shape design requires them, and are used as door and frame seals in the construction of industrial furnaces, laboratory furnaces and industrial driers.

Give us a challenge, we will meet it. Your requirement will be met with our technical know-how, experience and our top quality products.