The (chemical) textile finishing of our products is the core of HKO's development expertise. It is primarily about determining which material, base product (needle mat, fabric, multilayer), and finishing best solve the individual challenges of our customers. Our expertise lies not only in the in-house development of finishes and coatings but also in leveraging our know-how in combining various product components. We have the capability to rigorously test innovative and customer-specific finishes directly in our laboratory and can also draw on the expertise of our parent company Saint-Gobain and various research and development methods. All finishes are applied to the product in our integrated production process.

Technical Textile Finishing

Finishing options at HKO – our fully integrated process

Enhanced product features through finishing

Cut resistance, abrasion resistance, anti-fraying protection, or stiffening of the products.

Final products can be antistatic, conductive, and/or electrically insulating.

Achieving optimized fire resistance, resistance to radiant and contact heat, as well as insulation performance.

Discover our finishings

-

Lamination

-

Coating

-

Treatment

-

HKO Treatments

-

Finished yarns

Laminations for needle mats and fabrics

-

Stainless steel lamination

Stainless steel lamination- 50 micrometers

- Materials: AISI 304 / AISI 316L / AISI 321

- Flat or embossed

- Chemical resistance

- High rigidity

- Suitable for high-temperature industrial applications

- Available flat or embossed

-

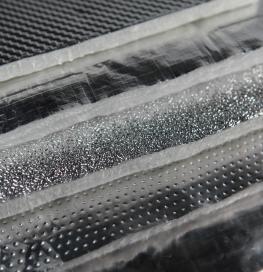

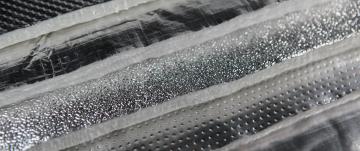

Aluminum lamination for needle mats

Aluminum lamination for needle mats- Temperature resistance depends on the carrier material and application

- 18-200 micrometers

- Highly reflective

- Sealed surface

- Suitable for all markets

- Options: Flat, grid-reinforced, embossed, and/or perforated

-

Aluminum lamination for fabrics

Aluminum lamination for fabrics- 10-50 micrometers

- Highly reflective

- Sealed surface

- Suitable for all markets

- Variants: Aluminized PET film, aluminized "Gold" PET film, aluminum transfer foil – ask our experts.

-

Mica lamination

- 80 – 200 g/sqm mica content

- Single-sided or double-sided E-glass grid

- Flame resistant (torch test)

- Excellent dielectric properties

- Used for multilayer structures (e.g., DEFENSOR-Flex® ML28)

- Available as natural or synthetic variant

-

PTFE lamination

- Temperature resistance from -54°C to +260°C

- From 12.5 micrometers; mainly 50 and 100 micrometers

- Single or double-sided lamination with a peeled PTFE film

- Mainly with LSR (Liquid Silicone Rubber) bonding

- Excellent chemical resistance

- Outstanding non-stick properties

- Low coefficient of friction (0.12–0.05, depending on pressure and speed)

- Conductive (black) or non-conductive

Need a quote or further infromation?

Coatings for fabrics

-

Silicone coating

Silicone coating- Temperature resistance from approximately -50°C to approximately +250°C with excellent flexibility

- High resistance to extreme mechanical, thermal, and electrical influences

- Good light stability, UV and oxidation resistance

- Mostly resistant to acids and alkalis

- Weatherproof

- Good dirt and oil repellent properties

- Good electrical insulating properties

- Available in various colors

- Up to 500/500 g per side IMO certified

- Variants: Topcoat silicone and transfer silicone – ask our experts

-

ITX coating

ITX coating- Intumescent (swelling/foaming) coating composition in a customized polymer matrix

- Possible expansion temperatures: approximately 150°C, 200°C, and 300°C - expansion rate depends on the filling degree of the mixture within the matrix

- Non-combustible

- Insulating/expanding (increasing the insulating surface) when exposed to heat

- Prevents the spread of flames

- Prevents the passage of smoke and toxic gases

- Mixing of different expansion temperatures possible

- Single-sided or double-sided alternatively

-

PU coating - G1/G2, W1/W2

PU coating - G1/G2, W1/W2G1/G2, W1/W2

- Increase in slip resistance and fray resistance

- Optionally single-sided (G1, W1) or double-sided (G2, W2)

- G1 and W1 are IMO certified

- Variants: G1F/G2F, G1"S"

G1 Shipyard

- Softer polymer coating for filament fabric

- Coatable on one side

- IMO certified

General properties:

- Free from solvents and halogens

- With aluminum pigments (except W1/W2)

- No thermal decomposition of the coating up to 200°C

- Maximum application temperature depends on the carrier material

-

PU coating - ALUFIX

PU coating - ALUFIX- Increase in slip resistance and fray resistance

- Optionally single or double-sided coating

- Free from solvents and halogens

- With aluminum pigments (except W1/W2)

- No thermal decomposition of the coating up to 200°C

- Maximum application temperature depends on the carrier material

-

PTFE coating

PTFE coating- Temperature resistance from -54°C to +260°C, temporarily higher (up to +315°C)

- Very good resistance to most chemicals, acids, and solvents

- Excellent non-stick properties

- Low coefficient of friction

- Available in various colors

- Types: static, antistatic (black)

-

Silverline coating

Silverline coating- Fire-resistant, highly reflective pigmented polymer coating

- Free from solvents and halogens

- No thermal decomposition up to 200°C

- Maximum application temperature depends on the carrier fabric

- Higher reflectivity due to highly reflective aluminum pigments

- Very low PCS value and low emission for PFP

Need a quote or further information?

Treatments for fabrics

-

Vermiculite treatment

Vermiculite treatment- Non-combustible, pure inorganic coating

- Temperature resistance of the pure coating up to approximately 1000°C

- Permanent temperature resistance (composite): up to approximately 750°C, or up to 1000°C (on silica fabric)

- Good slip resistance and fray resistance

- Minimization of smoke development

- Very high abrasion resistance

- Variants: AR also available as fabric coating

-

CS treatment

CS treatmentCS

- Flame-retardant surface

- Resistant up to a continuous temperature of approximately 700°C

- Temporarily resistant up to approximately 750°C

- Good slip-resistant properties and fray resistance

- Available in various shades

CS Shipyard

- Additionally: minimal dust deposition

- IMO certified

CS mintgreen

- Softer surface than CS

-

HT75 / HT90 treatment

HT75 / HT90 treatmentHT75

- Flame-retardant surface

- Resistant up to a continuous temperature of approximately 700°C

- Temporarily resistant up to approximately 750°C

- Good slip-resistant properties and fray resistance

- Available in various shades

HT90

- Special white coating for short-term temperatures up to 900°C

- Permanent temperature resistance up to approximately 750°C

- Stiffens the fabric

- Safe against metal splashes

-

Oleophobic treatment

Oleophobic treatment- Special colorless topcoat to improve oil tightness at room temperature for about three months (HKO internal method)

- Oil repellency/Grade 8 guaranteed for non-tempered materials (according to AATCC 118)

- Temperature resistance up to 200°C/4h (long-term) and 300°C/1h (short-term)

- No change in the flammability of the material

- Resistant to organic acids in normal concentrations, hard water, commercial diesel fuel, and gasoline drops

- Slight color deviations after exposure to temperature are possible

- IMO certified

Need a quote or further information?

HKO treatments for fabrics

-

Weld Guard Ocean Blue

- Temperature resistance up to 1,000°C in burner test

- Specifically developed for use in shipyards

- To improve abrasion resistance, fray resistance, and thermal resistance of large welder protective fabrics

- Improved resistance to metal splashes

- Improved resistance to flames

- IMO certified versions available

-

Weld Guard Anchor Grey

Weld Guard Anchor Grey- Resistant up to a continuous temperature of approximately 700°C.

- Temporarily resistant up to approximately 750°C

- Good slip-resistant properties and fray resistance

- Available in various shades

- IMO certified versions available

-

G-Tec

G-Tec- Grey special coating with metal oxide

- Thermal resistance up to 700°C (long-term) or temporarily (approximately 8 hours) up to 750°C

- Excellent abrasion resistance

- Flame retardant

- Available in various shades

G-Tec Ultra

- Enhanced smoke suppression through multi-stage chemical treatment

G-Tec Ultra "LE"

- Improved smoke suppression compared to G-Tec Ultra

- Barely noticeable color change at temperatures between 200°C and 400°C

-

Steel Blue

Steel Blue- Specially developed blue coating for SILICATHERM® fabric

- Temperature resistance up to approximately 1,200°C

- Increase in fabric tensile strength - good tensile strength even after 24 hours of thermal exposure at 1,100–1,200°C

- The blue color remains even after 24 hours at 1,100-1,200°C

-

SILONTEX®

SILONTEX®- Temperature resistance up to approximately 750°C

- Excellent resistance to molten metals, sparks, and hot slag

- Very good electrical insulating properties

- Improvement of abrasion resistance, fray resistance, and thermal resistance of the fabric

Need a quote or further information?

Finished and processed yarns

The optional use of refined or processed yarns can, among other things, make a significant contribution to the increased insulation performance of the end product. Refining the yarns through texturing, twisting, or chemical treatment leads to better thermal performance or results in altered mechanical properties. All refining processes are part of the in-house process.

-

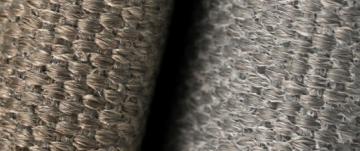

Texturized yarnsFor altered mechanical and physical properties. Texturized yarns have an increased volume and offer a more open structure for better insulation performance.

Texturized yarnsFor altered mechanical and physical properties. Texturized yarns have an increased volume and offer a more open structure for better insulation performance. -

Twisted yarnsFor altered mechanical and physical properties. Twisting two or more threads creates a more durable yarn with a larger diameter. Twisting the strands in the Z or S direction affects the tensile strength of the yarn and allows for the combination of different materials for hybridization.

Twisted yarnsFor altered mechanical and physical properties. Twisting two or more threads creates a more durable yarn with a larger diameter. Twisting the strands in the Z or S direction affects the tensile strength of the yarn and allows for the combination of different materials for hybridization. -

Finished yarnsIncrease of the temperature resistance of yarns through chemical treatment.

Finished yarnsIncrease of the temperature resistance of yarns through chemical treatment.